Pre painted aluminium coil and insulation aluminium foil are two of the most versatile and widely used aluminum products in the construction and industrial sectors. Known for their durability, lightweight nature, and resistance to corrosion, these materials offer strong performance for roofing, cladding, HVAC, insulation, and packaging solutions.

Specification of Pre Painted Aluminium Coil and Insulation Foil

| Item | Details |

|---|---|

| Alloy | 1050, 1060, 1100, 3003, 3105, 5052 |

| Temper | H14, H24, H26, etc. |

| Thickness | 0.20 mm – 1.5 mm |

| Width | 500 mm – 1600 mm |

| Coating Type | PE, PVDF, FEVE, epoxy |

| Surface Finish | Glossy, Matte, Embossed, Wood/Marble Design |

| Core (Foil) | Paper, Aluminum, or Customized |

| Application Temp | -40℃ to +120℃ |

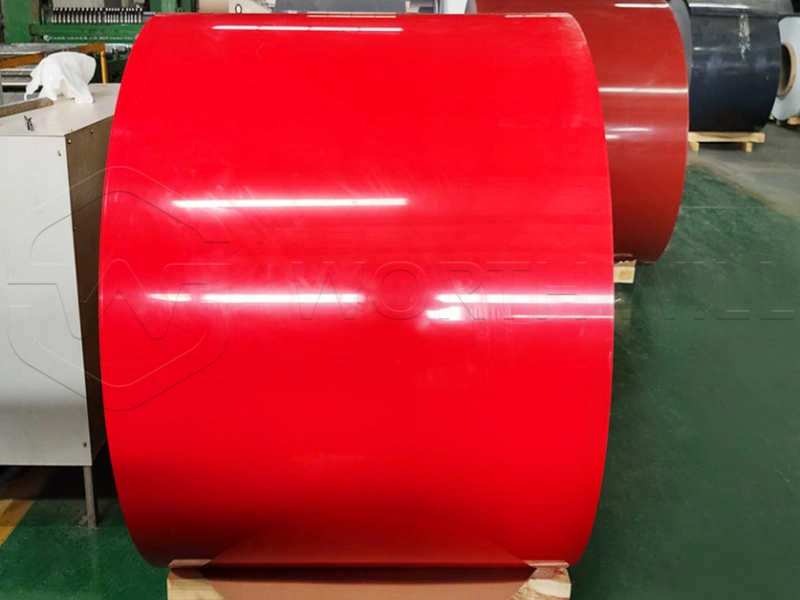

| Color | RAL colors or custom match |

| Packaging | Export standard packaging with film and pallet |

Classification

Pre Painted Aluminium Coil Types:

- PE Coated Coil – for general indoor/outdoor use

- PVDF Coated Coil – for high weather resistance

- Embossed Coil – for decorative or anti-slip purposes

- Wood/Marble Coil – for aesthetic architecture applications

Insulation Aluminium Foil Types:

- Single-sided Foil Insulation – foil laminated with kraft paper or PE

- Double-sided Foil Insulation – aluminium foil on both sides

- Bubble Foil – added thermal resistance with bubble wrap

- Foil Foam or Woven Backing – extra strength and flexibility

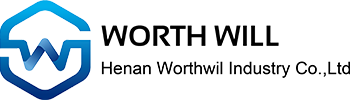

Pre Painted Aluminium Coil: The Versatile and Colorful Solution for Modern Industries

In the world of construction, manufacturing, and design, materials that offer both beauty and durability are highly prized. Among these, Pre Painted Aluminium Coil stands out as an exceptionally versatile and popular choice. Unlike raw aluminum, this innovative material arrives at its destination already coated with a vibrant, protective, and long-lasting finish. This pre-finishing process saves time, reduces costs, and opens up a world of design possibilities, making pre-painted aluminum a go-to material for a wide array of applications, from sleek building facades to durable appliance panels.

Understanding the benefits and uses of pre-painted aluminum coil can help businesses and designers make informed decisions, ensuring their projects are not only aesthetically pleasing but also built to last.

What is Pre Painted Aluminium Coil?

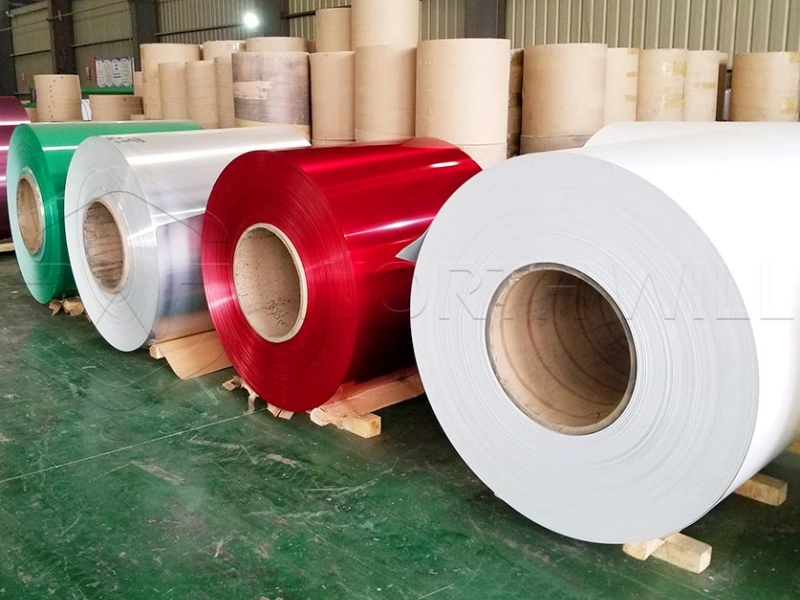

Pre Painted Aluminium Coil refers to large rolls of aluminum sheet that have been continuously coated with various paint systems before being cut into individual sheets or further processed. This “coil coating” process is highly automated and efficient, ensuring a uniform and high-quality finish across the entire surface of the aluminum.

The aluminum itself is typically of a specific alloy, chosen for its strength, formability, and corrosion resistance. Once the aluminum coil is manufactured, it undergoes a multi-stage cleaning and pre-treatment process to ensure excellent paint adhesion. Then, one or more layers of paint are applied and cured (baked) in high-temperature ovens. This creates a strong, durable bond between the paint and the metal. The finished painted aluminium coil is then ready to be shipped to manufacturers for fabrication into final products.

How is Pre Painted Aluminium Coil Made? (Simplified Process)

The creation of pre-painted aluminum coil involves a sophisticated, continuous process:

- Uncoiling: A large roll of plain aluminum coil is fed into the production line.

- Cleaning and Pre-treatment: The aluminum surface is thoroughly cleaned to remove oils and dirt, then chemically treated to enhance paint adhesion and corrosion resistance.

- Paint Application: Liquid paint is applied evenly to one or both sides of the coil using precision rollers.

- Curing (Baking): The painted coil passes through high-temperature ovens, where the paint is baked and cured, forming a hard, durable finish.

- Cooling: The coil is rapidly cooled.

- Rewinding: The finished color coated aluminium coil is rewound into a new, compact roll, ready for shipping.

This continuous process ensures consistent quality, thickness, and color across thousands of meters of material.

Key Features and Advantages of Pre Painted Aluminium Coil

The widespread adoption of pre painted aluminium coil is driven by its numerous benefits:

- Superior Aesthetics: Available in an almost limitless range of colors, finishes (matte, gloss, metallic), and even patterns (wood grain, stone), offering immense design flexibility. Color coated aluminum provides a consistent, high-quality look.

- Excellent Durability: The baked-on paint finish is highly resistant to chipping, cracking, peeling, and fading. It also offers excellent resistance to weathering, UV radiation, and corrosion, making it ideal for outdoor applications.

- Corrosion Resistance: Aluminum itself is naturally resistant to rust. When combined with a protective paint layer, its corrosion resistance is significantly enhanced, particularly in harsh environments.

- Lightweight: Aluminum is much lighter than steel, making pre-painted aluminum sheets easier to handle, transport, and install. This can reduce structural loads in buildings and improve fuel efficiency in vehicles.

- High Formability: Despite being painted, the coil retains the inherent ductility of aluminum, meaning it can be bent, cut, stamped, and formed into complex shapes without damaging the paint finish.

- Cost-Effective: While the initial cost per coil might be higher than raw aluminum, the elimination of post-painting processes (which are often labor-intensive, time-consuming, and require specialized facilities) results in significant overall cost savings.

- Environmentally Friendly: The coil coating process is highly efficient, with minimized waste and volatile organic compound (VOC) emissions compared to post-painting. Aluminum is also 100% recyclable.

- Consistent Quality: The automated coil coating line ensures a uniform paint thickness and color consistency across the entire batch, reducing variations and improving product quality.

Common Applications of Pre Painted Aluminium Coil

The versatility of pre painted aluminium coil makes it an indispensable material in a vast range of industries:

- Building & Construction:

- Roofing: Durable and lightweight roofing sheets for residential, commercial, and industrial buildings.

- Wall Cladding and Facades: Used for exterior wall panels, curtain walls, and decorative elements due to its aesthetic appeal and weather resistance.

- Ceilings: Interior ceiling panels for offices, hospitals, and homes.

- Rain Gutters and Downspouts: Corrosion-resistant and long-lasting solutions for water drainage systems.

- Door and Window Frames: Provides a durable and attractive finish.

- Garage Doors: Lightweight and weather-resistant.

- Appliance Industry:

- Refrigerators: Exterior panels that are durable and easy to clean.

- Washing Machines and Dryers: Outer casings.

- Microwave Ovens, Dishwashers, Air Conditioners: Various external and internal components requiring a finished surface.

- Transportation:

- Automotive Parts: Interior and exterior trim, body panels.

- Caravans and RVs: Lightweight and durable exterior panels.

- Buses and Trains: Interior wall panels and decorative elements.

- Signage and Advertising:

- Outdoor Signs: Provides a weather-resistant and colorful base for advertising boards, road signs, and billboards.

- Display Panels: For retail environments and exhibitions.

- Consumer Goods:

- Furniture: Decorative panels for cabinets, tables, and shelves.

- Lighting Fixtures: Reflective surfaces and decorative elements.

- Electronic Casings: Durable and aesthetically pleasing enclosures for various electronic devices.

- Other Industrial Uses:

- HVAC Ducting: Internal and external panels for air conditioning and ventilation systems.

- Insulation Jacketing: Protective outer layer for pipe insulation.

Types of Paint Coatings for Pre Painted Aluminium Coil

The performance and appearance of pre painted aluminium coil largely depend on the type of paint coating used. Common types include:

- Polyester (PE): A widely used, cost-effective coating offering good weather resistance and color retention. Suitable for general outdoor and indoor applications.

- Fluorocarbon (PVDF/PVF2): Highly durable coatings known for excellent UV resistance, color stability, and chalk resistance. Ideal for exterior architectural applications where long-term performance is critical.

- Silicon Modified Polyester (SMP): Offers improved hardness and scratch resistance compared to PE, with better fade resistance. A good mid-range option.

- Epoxy: Primarily used for primer coats due to its excellent adhesion and corrosion resistance.

- Acrylic: Offers good hardness and gloss, often used for indoor decorative applications.

Choosing the Right Pre Painted Aluminium Coil

When selecting pre painted aluminium coil for your project, consider these factors:

- Application: Will it be used indoors or outdoors? What kind of environmental exposure will it face (UV, humidity, chemicals)?

- Paint System: Choose the appropriate coating type (PE, PVDF, SMP) based on required durability, color retention, and warranty.

- Aluminum Alloy: Different alloys offer varying levels of strength and formability. Common choices include 1100, 3003, 3105, and 5052 series.

- Thickness and Width: Match these to your design and fabrication requirements.

- Color and Finish: Select based on aesthetic preferences and design specifications.

- Formability Requirements: Ensure the chosen coating can withstand the bending and forming processes without cracking or delaminating.

- Supplier Reputation: Partner with a reputable pre-painted aluminum supplier to ensure consistent quality and compliance with industry standards.

Conclusion

Pre Painted Aluminium Coil is a true game-changer in the world of materials. By combining the inherent advantages of lightweight, durable, and corrosion-resistant aluminum with a meticulously applied, long-lasting, and aesthetically pleasing paint finish, it offers an unparalleled solution for countless industrial and commercial applications. Its cost-effectiveness, environmental benefits, and sheer versatility make color coated aluminum an intelligent choice for architects, manufacturers, and designers aiming for high-quality, durable, and visually appealing results. Embrace the power of pre-painted aluminum for your next project and discover its lasting value.