Painting aluminum is a common industrial and decorative process used to protect metal surfaces and improve appearance.

Aluminum can be painted, but the surface must be prepared correctly.

Our factory provides high-quality aluminum surface treatment and coating solutions with stable production, fast delivery, and reliable quality.

What Kind of Paint Do You Use on Aluminum?

Not all paint works well on aluminum.

The best choice is paint designed for metal surfaces.

Recommended Paint Types

| Paint Type | Feature | Application |

|---|---|---|

| Acrylic metal paint | Good adhesion | Indoor use |

| Epoxy coating | Strong protection | Industrial use |

| Polyester coating | Weather resistance | Outdoor panels |

| Spray metal paint | Smooth surface | Decorative aluminum |

High-quality coating improves durability.

Do You Have to Prime Aluminum Before Painting?

Yes, priming aluminum is highly recommended.

Priming helps paint stick better and prevents peeling.

Surface Preparation Steps

- Clean aluminum surface

- Remove oil and dust

- Polish rough areas

- Apply metal primer

- Wait primer drying time

This process is important when painting bare aluminum.

Painting Bare Aluminum

Painting bare aluminium requires special treatment.

Bare aluminum surface is smooth and non-porous.

Without primer, paint may peel.

Recommended process:

- Use metal primer

- Apply thin paint layer first

- Add second coating after drying

Painting Anodized Aluminium

Painting anodized aluminium is possible but requires surface testing.

Anodized aluminum already has oxide protection layer.

Key tips:

- Light sanding before painting

- Use adhesion primer

- Avoid thick coating

Painting Polished Aluminium

Polished aluminum surface is very smooth.

This surface needs strong bonding primer.

Common method:

- Clean surface carefully

- Apply metal bonding primer

- Use spray painting for uniform coating

Painting Aluminium Panels

Painting on aluminum panels is widely used in construction.

| Panel Thickness | Application |

|---|---|

| 0.5 – 1.0 mm | Decoration panels |

| 1.0 – 2.0 mm | Exterior wall panels |

| 2.0 mm+ | Structural panels |

Painting Aluminum Foil

Painting on aluminium foil is more difficult.

Because foil is very thin.

Best method:

- Use spray coating

- Apply very light paint layer

Painting Aluminum Gutters

Painting aluminium gutters improves building appearance.

Advantages:

- Rust protection

- Color customization

- Longer service life

Outdoor coating must be weather resistant.

Spray Paint vs Brush Paint Aluminum

| Method | Result | Recommendation |

|---|---|---|

| Spray paint | Smooth surface | Best choice |

| Brush paint | Visible brush marks | Small repair use |

Spray painting is usually better.

Common Mistakes When Painting Aluminum

Avoid these errors:

- Skipping primer

- Painting dirty surface

- Using wrong paint type

- Applying thick layer quickly

- Ignoring drying time

Correct preparation is very important.

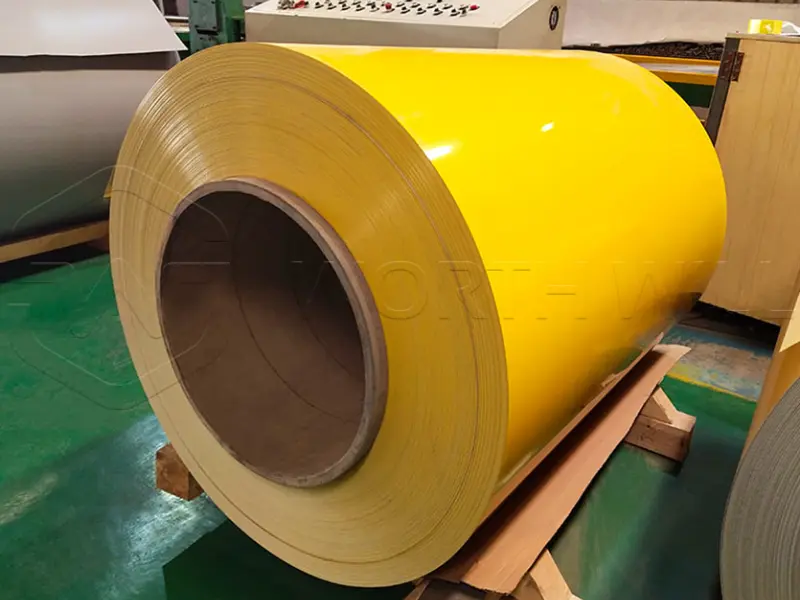

Applications of Painted Aluminum

Painted aluminum is widely used in many industries:

- 🚗 Transportation equipment

- 🏢 Building decoration panels

- 🏠 Exterior wall systems

- 🪟 Window and door frames

- 🧰 Industrial equipment

- 🎨 Advertising panels

- 🌊 Marine environment protection

Why Choose Our Factory?

Our company focuses on aluminum surface processing and coating production.

Production Advantages

- Fast production line

- Accurate coating thickness control

- Professional quality inspection

- Stable product performance

- Long-term customer cooperation

We have many years of manufacturing experience.

Comparison With Other Suppliers

| Factor | Our Factory | Others |

|---|---|---|

| Price | Reasonable | Often higher |

| Quality stability | High | Variable |

| Production speed | Fast | Slower |

| Technical support | Professional | Limited |

| Long-term supply | Stable | Uncertain |

Production Time

| Order Type | Time |

|---|---|

| Standard order | 3–7 days |

| Custom coating | 7–12 days |

| Bulk production | 10–15 days |

What Makes Our Products Reliable?

- Strict raw material selection

- Professional coating technology

- Experienced production team

- International export quality standard

Many clients cooperate with us for long time.

Frequently Asked Questions

Is it better to spray paint aluminum?

Yes, spray paint usually gives smoother and more uniform coating.

Do you need primer before painting aluminium?

Yes, primer improves adhesion and prevents peeling.

Can aluminum be painted outdoors?

Yes, if weather-resistant coating is used.

painting aluminium panels for sale

Painting aluminum is an important metal surface treatment technology.

Whether you need painting aluminum panels, painting anodized aluminum, or painting bare aluminum, proper surface preparation is essential.

Our factory provides high-quality aluminum coating solutions with fast production, reasonable price, and long-term reliable performance.

If you need professional aluminium painting products, contact us for customized solutions.