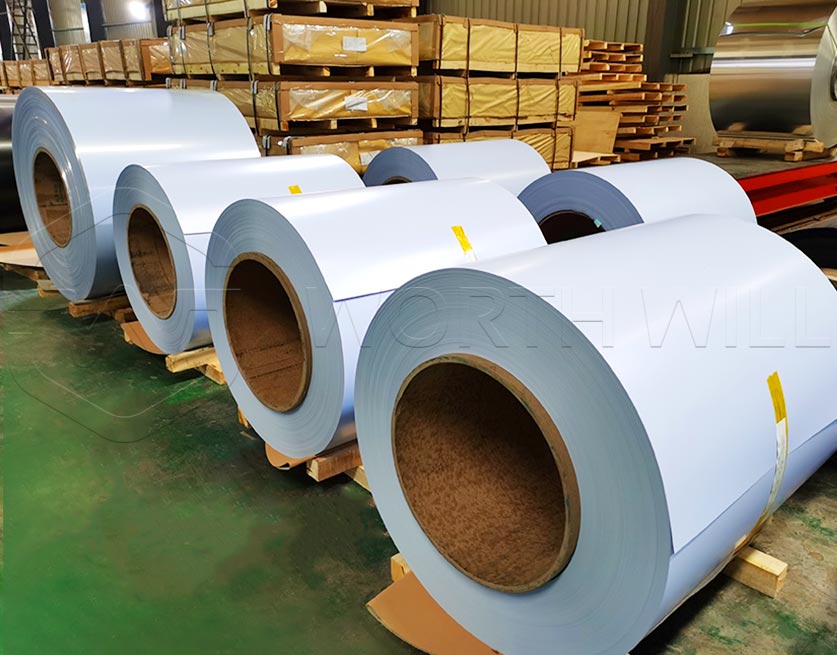

Color coated aluminum, commonly divided into PE and PVDF coatings, offers a myriad of applications and benefits. In this detailed introduction, we will explore the distinctions and similarities between PE and PVDF coatings, delve into the processing techniques, advantages, applications, and unique characteristics of various alloy compositions.

PE PVDF Coatings:

1.PE Coating (Polyester): Known for its cost-effectiveness and versatility, PE coating provides a smooth, glossy finish to the aluminum surface. While offering good weather resistance and color retention, it is more susceptible to fading and chalking over time compared to PVDF.

2.PVDF Coating (Polyvinylidene Fluoride): Renowned for its exceptional durability and resistance to harsh environmental conditions, PVDF coating ensures long-lasting protection against UV rays, weathering, and chemical exposure. It offers superior color retention, making it ideal for exterior applications where color consistency is crucial.

Advantages of Color Coated Aluminum:

- Enhanced Aesthetics: Color coated aluminum offers a wide spectrum of colors and finishes, adding aesthetic appeal to architectural elements, signage, and consumer products.

- Durability and Weather Resistance: With superior coatings like PVDF, color coated aluminum exhibits excellent resistance to fading, chalking, and corrosion, ensuring longevity in outdoor applications.

- Ease of Maintenance: The smooth, non-porous surface of color coated aluminum makes it easy to clean and maintain, reducing maintenance costs and efforts.

Applications of Color Coated Aluminum:

- Building and Construction: Used for exterior cladding, roofing, facades, and decorative elements in commercial and residential buildings.

- Transportation: Ideal for interior and exterior panels in automotive, marine, and aerospace industries due to its lightweight, corrosion-resistant properties.

- Consumer Products: Widely employed in the manufacturing of appliances, furniture, electronics, and consumer goods for its aesthetic appeal and durability.

Characteristics of Different Alloy Compositions:

- 1xxx Series: Pure aluminum alloy offering excellent corrosion resistance and formability, suitable for indoor applications and decorative purposes.

- 3xxx Series: Alloyed with manganese, providing enhanced strength and formability, ideal for roofing, signage, and architectural applications.

- 5xxx Series: Incorporating magnesium, offering superior weldability and corrosion resistance, widely used in outdoor structures, transportation, and marine applications.

The Coating Processing Line

- Put the plain coils in the decoiling machine and let it trough the Material storage tower.(To prevent turn off the whole processing line when we change new coil)

- Pre-processing. Firstly through the alkaline water tank to degrease the coil,secondly use the tap water to clean, then the acid to neutralize the remnant alkali, at last completely clean with pure water.

(the temperature is 210-230 degree Celsius).

- Add the chromium to passivate the coil and enhance the adhesive strength.

- Coat the bottom of the coils with clear varnish or white and gray paint.

Drying.

- Use air cooling system or water cooling system to cool them down.

- Drying again.(water cooling system)

- According to customers’ requirement to make second coating.

- Cooling

- Covering the surface of coils with plastic film.

- Packaging with inner paper tube about 15-20mm in thickness.

- Sending them to the storage.

Colors

Different products have the different colors. We provide solid color like black and white, and metallic color as metallic silver silver gray, also other bright colors include bright red and bright yellow. And also we have mirror aluminum and beushed aluminum.

One of the most important is we can custom product color by customer demand.

China Color Coated Aluminum

Coated aluminum stands as a versatile, durable, and aesthetically pleasing material with a wide range of applications across various industries. Whether it’s enhancing the architectural beauty of buildings or providing durable solutions for transportation, color coated aluminum continues to redefine possibilities in modern design and construction. Contact us today to explore our comprehensive range of color coated aluminum products tailored to your specific requirements and applications.