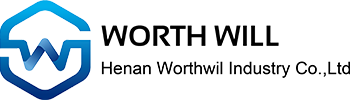

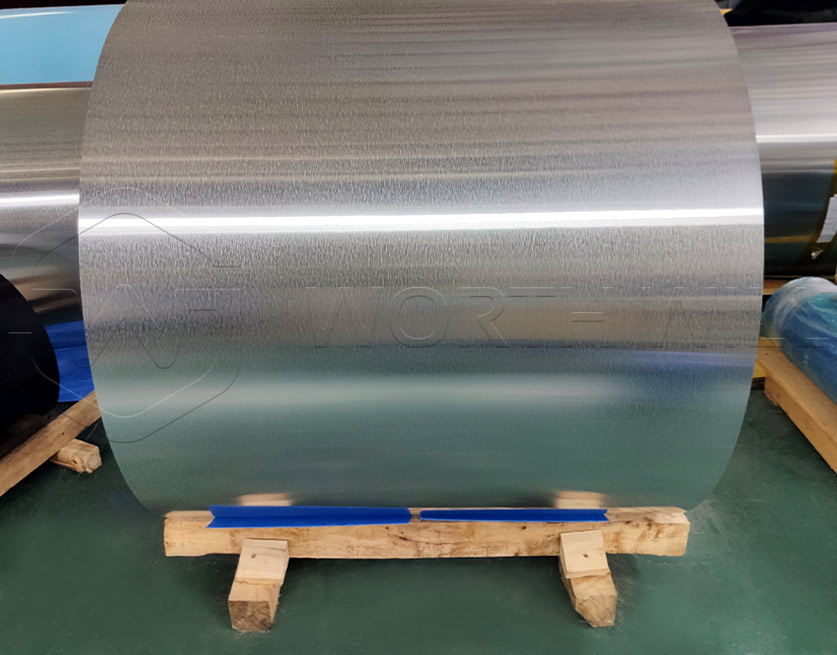

Brushed aluminum, also known as brushed aluminum alloy, undergoes a surface treatment process that imparts a unique textured finish characterized by fine parallel lines. This distinctive appearance is achieved by mechanically brushing the surface of the aluminum sheet with abrasive material, resulting in a sleek and elegant aesthetic.

Specification

Alloy | 1050, 1060, 3003, 5052 etc. |

Temper | O, H 12, H18, H24,H36, H112 etc. |

Coating thickness | As per customer’s requests |

Base aluminum size | 0.45-1.35mm x 900-1350mm x C |

Surface treatment | Brushed, Color Coated |

Colors | Gold, Black, Silver, Grey etc. |

MOQ | 3-5 tons |

Advantages of Brushed Aluminum:

Brushed aluminium stands out for its numerous advantages, making it a preferred choice across various industries.

- Durability: Its enhanced durability ensures resistance to scratches, abrasions, and corrosion, thereby prolonging its lifespan and maintaining its pristine appearance over time.

- Excellent formability: Brushed aluminium offers excellent formability, allowing for easy fabrication into different shapes and designs to meet specific requirements.

- Lightweight: Its lightweight nature makes it ideal for applications where weight reduction is essential, without compromising on strength and structural integrity.

- Thermal conductivity: Brushed aluminium exhibits thermal conductivity, making it suitable for applications requiring heat dissipation, such as electronic enclosures and heat sinks.

Applications of Brushed Aluminum:

The versatility of brushed aluminium lends itself to a multitude of applications across diverse industries.

- In the architectural sector, brushed aluminium finds usage in exterior cladding, wall panels, and decorative elements, adding a modern and sophisticated touch to building facades.

- Its corrosion resistance makes it ideal for outdoor signage, ensuring longevity and visual appeal in various environmental conditions.

- In the automotive industry, brushed aluminium is utilized for interior trim, dashboard accents, and door panels, elevating the interior aesthetics of vehicles.

- Furthermore, brushed aluminum is widely employed in the manufacturing of consumer electronics, furniture, kitchen appliances, and jewelry, where its sleek appearance and durability are highly valued.

Colors Of Brushed Aluminum

As a decorative sheet, there are various colors of brush sheet. A variety colors are available, such as silver, gold, light gold, tea gold, black, etc. And also we can according to customer requirement to customize colors.

If you have requirements, don’t hesitate to contact us. We will try our best to satisfy your requirement.

Technique

Laminated is an important technique in the process of aluminum sheet. During the process of aluminum sheet under pressure, in order to obtain the required cross-sectional area shape and size, we need to through the external force to achieve the goals.

The lamination process can make the aluminum plate more rigid and durable. And the color is not easy to fall off.

Brushed Aluminum Sheet Suppliers

WORTHWILL is the foreign trade department of Henan Jinyu. We are a foreign trade company which specializes in the production and supply of aluminum products. Aluminum products include aluminum sheets, aluminum coils, aluminum circles, and so on.

Although the foreign trade company has only been established for more than three years. And our factory has 14 years of production experience.

The brushed aluminum sheet is a high-end type of aluminum sheet, its price is a little higher than the common price. As a brushed aluminum sheets supplier, we can offer you the best price. Welcome to leave a message below to get our latest quotation.

Contact us for customized sizes or special requests.