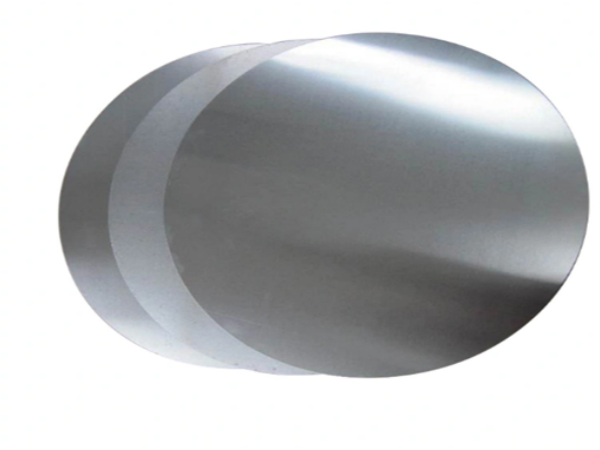

Aluminum circle is a common aluminum material, widely used in aviation, aerospace, electronics, transportation and other fields. With the development of society and scientific and technological progress, the prospects of the aluminum wafer industry are also very broad.

Specification Of Aluminum Circle

Item | Aluminum/aluminium disc/ round wafer |

diameter | 92-780mm(or as per requirements) |

Thickness | 0.2-10mm(or as per requirements) |

Series | 1050 1060 1070 1100 3003 5052 |

Temper | O H12 H14 H32 |

Package | Standard seaworthy exporting packing |

MOQ | 2-4 tons |

Advantages Of Aluminum Circle:

Aluminium circle, crafted from alloys such as 1050, 1060, 1100, and 3003, offer numerous advantages:

- Exceptional Durability: Aluminum’s innate strength and resilience make our circledurable, ensuring long-term reliability in diverse applications.

- Corrosion Resistance: Aluminum’s natural oxide layer provides excellent resistance to corrosion, ensuring prolonged service life even in harsh environments.

- Lightweight Nature: Compared to other metals, aluminum is lightweight, facilitating ease of handling, transportation, and installation.

- Excellent Thermal Conductivity: aluminum circle boast impressive thermal conductivity, making them ideal for applications requiring efficient heat dissipation.

- Versatility: Our aluminum circle find applications across a wide spectrum of industries, including automotive, aerospace, electronics, and cookware manufacturing.

Applications of Aluminum Circle:

The versatility of aluminium circle makes them indispensable in various applications, including but not limited to:

- Cookware Manufacturing: aluminium circle serve as the primary material for producing high-quality cookware such as pots, pans, and utensils due to their excellent heat conductivity and lightweight nature.

- Automotive Industry: These clrcle are utilized in automotive components such as wheel rims, brake circle, and transmission housings owing to their lightweight yet robust properties, contributing to fuel efficiency and overall performance.

- Electronics Sector: aluminum circle find application in electronic devices and components where thermal management is crucial, ensuring efficient heat dissipation and prolonging the lifespan of electronic systems.

- Aerospace Engineering: aluminum circle are integral to the aerospace industry, where they are utilized in the fabrication of aircraft components, including fuselage panels, wing ribs, and structural reinforcements, owing to their lightweight yet sturdy characteristics.

Process:

Our company employs state-of-the-art manufacturing techniques to produce premium-quality aluminum circle. The manufacturing process typically involves the following steps:

Material Selection: We carefully select high-grade aluminum alloys, including 1050, 1060, 1100, and 3003, to ensure optimal performance and durability.

Casting: The selected aluminum alloys are melted and cast into ingots or billets, which serve as the raw material for the disc manufacturing process.

Hot Rolling: The ingots or billets are hot rolled into sheets of the desired thickness, which are subsequently cut into circular blanks.

Cold Rolling: The circular blanks undergo cold rolling to achieve the desired thickness and surface finish, ensuring dimensional accuracy and uniformity.

Annealing: The cold-rolled circle are annealed to relieve internal stresses and enhance their mechanical properties, including strength and ductility.

Cutting and Finishing: Select the size of the mold that the customer wants to punch out the aluminum circle and subjected to surface finishing processes such as polishing or coating to meet customer’s requirements.

Packaging

We pack the goods on the basis of your requirement, but finally, we hope to negotiate to take the most suitable packaging method, to avoid unnecessary loss. When packing goods, we usually use plastic or craft paper cover the surface, then adopt the wooden case protect products from damage during the delivery.

Aluminum Circle Supplier

Our company’s aluminium circle represent a hallmark of quality, offering unparalleled durability, versatility, and performance across various industries. With a meticulous manufacturing process and a focus on superior materials, we ensure that our aluminum circle meet the highest standards of excellence, catering to the diverse needs of our esteemed clientele. Worthwill’s products has exported to many countries such as Europe, Asia, America and Oceania.